Fulcrum Racing Zero Carbon Competizione DB C19 Disc Center Lock Wheelset

$341.00 Original price was: $341.00.$95.99Current price is: $95.99.

- No-Questions-Asked Returns

- Your satisfaction is 100% guaranteed.

- fast shipping

- Where quality meets convenience.

Racing Zero Carbon Competizione DB C19 Disc Center Lock wheelset by Fulcrum – combining carbon with innovation

The Fulcrum Racing Zero Competizione DB C19 Disc Center Lock wheelset made of carbon combines a 19 mm internal width with the 2-Way Fit rim profile, allowing the fitting of tubeless tyres of 23 mm and more. The installed CULT™-bearings contain high-quality ceramic balls with extremely precise surfaces, which allows a lubrication of the balls with a thin oil film instead of normal grease. This drastically reduces the friction in the bearing and thus significantly improves the smoothness of the wheels. The Fulcrum 2:1 lacing pattern guarantees a symmetrical ride despite the asymmetrical design, making the wheel more responsive to acceleration.

Specifications:Application:RoadWheel Size:28″Tyre Type:clincher tyreNumber of Spokes:21Brake Type:Center Lock Disc (AFS Axle System™)Tubeless System:2-Way FitTechnical Information – Rim:Dimensions (ETRTO):19-622Inner Width:19 mmOuter Width:26.5 mmDepth:30 mmValve Hole Diameter:SV/Presta (6.5 mm)Rim Material:CarbonTechnical Information – Front Hub:Over Locknut Dimension:12 x 100 mm thru-axleBearings:CeramicBody Material:carbon w/ aluminium flangesTechnical Information – Rear Hub:Over Locknut Dimension:12 x 142 mm thru-axleBearings:CeramicBody Material:aluminium w/ aluminium flangesTechnical Information – Lacing:Front Lacing Pattern:2:1 Two-to-One™ (14 l / 7 r)Rear Lacing Pattern:2:1 Two-to-One™ (7 l / 14 r)Spoke Type:aero, with straight headSpoke Material:aluminiumNipple Material:aluminiumApproved For:Weight Limit:120 kg (system weight)Recommended Tyre Width:23 – 40 mmFeatures:ASTM category 2: for use on roads, maintained dirt roads and gravel roads (on Touring and Cross Country bikes) with jumps up to a height of 15 cmCULT ceramic bearingsTwill carbon fibre surfaceoversized aluminium flanksPlasma freehubincl. DRP kit, an additional seal kit to protect the bearings from rain, mud or dust during Gravel or CX useTechnology:2-Way Fit™

Tubeless technology was first used in the automotive sector, then in motorcycles and finally in bicycles. After entering the MTB world, the time has come for their use on the road: Fulcrum has developed the 2-Way Fit technology to guarantee the perfect compatibility of Fulcrum tubeless rims even with normal clincher tyres with tubes. 2-Way Fit wheels are particularly versatile and therefore perfectly suited to every situation. Thanks to a special marking in the valve area, the tubes are mounted with high precision and the tube remains firmly stabilized in the clincher tyre. The valve for tubeless tyres can also be used safely. This offers the undeniable advantage that air can never penetrate during assembly due to inaccurate positioning.

The advantages are undisputed: tests have shown an incomparably high increase in smoothness. The absence of a tube prevents friction with the tyre and the perfect adhesion of the tyre to the rim prevents energy loss. A tubeless tyre cannot lose air abruptly through a hole and suddenly become flat, which is a clear safety advantage. There is also no danger of snake bites, as there is no tube that can be punctured.

What about a flat tyre? Don’t worry! One of the advantages of the Fulcrum 2-Way Fit system is the possibility of removing the tubeless valve and inserting a normal tube to get you home.

AFS Axle System™

The Axial Fixing System is the solution developed by Fulcrum to mount the disc rotor to the hub. The connection provided by the stop surface of the mount is greater than that of the already known standards, allowing greater structural rigidity and therefore more precise and efficient braking.

Anti Rotation System™

This system takes the concept of the lacing system to a new level of performance. Fulcrum’s technicians have redesigned the spokes and hub shells to create a strong and solid unit. In this way, the spokes a) never lose their initial tension, keeping the wheel perfectly reactive and trued, and b) remain in the position developed in the wind tunnel to ensure the best possible aerodynamics.

CULT™

CULT stands for Ceramic Ultimate Level Technology. It is the technology developed, carefully perfected and then exclusively used by Fulcrum.

CULT is based on the exclusive stainless steel Cronitect®, a product of ” Advanced by FAG” , part of the Schaeffler Group, and is used in the manufacturing of ball bearing surfaces.

It is an extremely hard and corrosion-resistant stainless steel, in which the upper layer is made particularly resistant to corrosion by means of a thermochemical machining process.

The end result? Amazing: The wheels with CULT bearings/balls are even nine times smoother running than those with conventional bearings. An advantage that can easily be translated into a great plus in terms of energy saving and in terms of reducing the number of seconds, if not minutes.

2:1 Two-to-One™

At the moment when the rider pedals

| Ausführungen | black/28" set (front 12×100 + rear 12×142) Campy, black/28" set (front 12×100 + rear 12×142) Shimano |

|---|

Be the first to review “Fulcrum Racing Zero Carbon Competizione DB C19 Disc Center Lock Wheelset” Cancel reply

Related products

Front Derailleurs

Shifters & Derailleurs

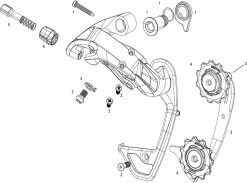

SRAM HEX5 B-Bolt & Limiter Kit For X01 DH/GX DH 7-speed Rear Derailleurs

Shifters & Derailleurs

Derailleur Pulleys

Shifters & Derailleurs

Reviews

There are no reviews yet.